21 Expert Insights to Buy Geely Brake Pads from China – Quality, Standards & Industrial Sourcing Guide

Introduction: Why Global Buyers Choose China for Brake Pads

G.Sparts supports procurement teams, fleet operators, and aftermarket distributors who buy Geely brake pads from China with confidence. This guide explains how formulas are developed, how ASTM and SAE standards ensure consistency, and why large-scale Chinese production makes cost-effective sourcing possible. You will learn how base materials, steel backing plates, and NVH control features come together, and how QA testing secures safety and durability. With disciplined supplier audits, you can reduce risk, shorten timelines, and deliver better value to your end customers when you buy Geely brake pads from China.

Composition of Geely Brake Pads

Friction Families

When buyers buy Geely brake pads from China, they can choose between three primary families:

- NAO/Ceramic: optimized for low dust and quiet braking.

- Semi-metallic: higher metal content for better heat dissipation.

- Low-metallic: improved initial bite and recovery, though with higher rotor wear.

Controlled Formulation

When you buy Geely brake pads from China, composition is more than a marketing term—it is a controlled recipe. Typical inputs include aramid or mineral fibers for reinforcement, graphite for lubrication, metal powders for heat conduction, and barite or ceramic fillers for stability, all combined with resol or novolac phenolic resins. Substituting copper has accelerated to meet environmental rules, so modern mixes rely on tin, graphite, or tungsten modifiers to carry heat and preserve friction films. The underlayer cushions the friction block and supports adhesive bond strength to the steel backing plate, mitigating shear stress spikes during thermal cycles. Use mechanical retention features to boost shear strength without over-reliance on adhesive thickness.

Industry Standards & Certifications

SAE & ASTM Benchmarks

Standards give confidence when you buy Geely brake pads from China:

- SAE J866: classifies friction level (μ code).

- SAE J661: Chase test, evaluating fade and recovery.

- ASTM: references test methods for materials and coatings.

ECE R90 Approval

For Europe, ECE R90 type-approval ensures aftermarket pads match OEM performance. Without this certification, importing pads is impossible in regulated markets. ISO 6312 shear tests also confirm bond strength. These benchmarks make sourcing structured and defensible.

Backing Plates & Noise Control

Backing plates remain the backbone when you buy Geely brake pads from China. Most employ low-carbon steel plate stamped to pattern with abutment cutouts, followed by shot-blasting, phosphate treatment, and powder coating. Increasingly, mechanical retention features—hooks, dovetails, or undercut holes—are formed to raise shear strength by interlocking the compound. Noise-control shims bonded with high-temperature PSA or silicone adhesives help interrupt vibration loops between piston, pad, and caliper. Premium sets combine multilayer stainless shims with edge chamfers and slots to manage gas, dust, and pressure distribution across the contact patch. Implement barcode or QR traceability linking batch IDs to material certificates and test reports.

Manufacturing Processes in China

Step-by-Step Flow

Factories use a disciplined workflow when you buy Geely brake pads from China:

- Raw material inspection.

- Mixing under controlled humidity.

- Hot pressing to form pads.

- Curing and post-curing to stabilize resins.

- Slotting, chamfering, scorching.

- Bonding to steel plates.

- Powder-coating and shim assembly.

- Testing, marking, and packaging.

QA Integration

SPC tracks press pressure, temperature, and cure cycles. This rigor ensures consistency across batches and gives assurance to importers.

Quality Assurance & Testing

Laboratory Testing

- ISO 6312 shear: checks adhesive bond.

- SAE J661 Chase: measures μ stability.

- Inertia dynamometer: validates performance against vehicle duty cycles.

NVH & Durability

Quality assurance begins long before you buy Geely brake pads from China. Suppliers should maintain incoming inspection for particle size distribution, resin viscosity, and moisture. In-process SPC tracks press pressure, mold temperature, and cure time. Finished parts undergo thickness, hardness, density, and compressibility checks, plus ISO 6312 shear and dynamometer validation against the drawing. For export, lot traceability should link heat numbers for plate steel, mix batch IDs, adhesive lot codes, and test reports, simplifying root-cause analysis if any market feedback arises. Train operators to remove swarf and dust, preventing inclusion defects before bonding.

Applications Across Geely Models

Applications for Geely platforms are diverse, which affects how you buy Geely brake pads from China. Compact sedans prioritize low dust and comfort with NAO/ceramic formulas, while heavier SUVs need higher heat capacity and structural stiffness in the backing plate. Fleet duty cycles—taxis, ride-hailing, and delivery—favor longer wear and strong recovery after fade. Performance trims may pair semi-metallic pads with high-carbon rotors to resist thermal cracking. Always match pad compressibility to caliper characteristics to manage pedal travel, bite progression, and noise. Deploy automated inspection to detect cracks, chips, and surface contamination on pad faces.

Sourcing Strategy & Factory Audits

Companies that buy Geely brake pads from China should audit:

- Lab accreditations.

- PPAP and FMEA documentation.

- Capacity, tooling, and contingency plans.

- Traceability of raw materials.

A transparent supplier provides test reports, process logs, and third-party certifications.

Environmental & Regulatory Compliance

Environmental compliance is key when you buy Geely brake pads from China:

- Copper-free formulations meet new legislation.

- VOC control in coatings protects workers.

- Steel backing plates are recyclable.

- Many plants publish Environmental Product Declarations (EPDs).

This ensures sustainability alongside performance.

Logistics, Packaging & Export

Long shipping routes require protective packaging. Buyers who buy Geely brake pads from China should request:

- ISTA-certified packaging tests.

- Moisture barrier bags with desiccants.

- QR-coded cartons for traceability.

- Palletization plans to maximize container efficiency.

For buyers who buy Geely brake pads from China routinely, logistics can be the hidden profit center. Optimize carton geometry, palletization, and moisture-barrier packaging for ocean voyages. Use humidity indicators and desiccants; specify drop-tests and compression tests to ISTA standards. Coordinate production cycles with vessel cutoffs and buffer inventory near destination to maintain service levels. Smart labeling—QR lot IDs linked to digital certificates—accelerates receiving, customs clearance, and warranty traceability. Avoid copper contamination where regional regulations restrict copper in friction materials. Use thermal imaging during dyno tests to monitor hot spots and correlate to torque fade.

Material Science & Rotor Interactions

Pad performance is tied to rotor metallurgy. Stable transfer films reduce judder and noise. When you buy Geely brake pads from China, ensure suppliers document rotor compatibility and bedding procedures. Testing confirms consistent μ and prevents uneven wear.

Cost Engineering & Value Optimization

Cost engineering is a strength of supply chains where many brands buy Geely brake pads from China. However, true savings come from balance, not shortcuts. Reducing backing-plate thickness might lower weight but risks flex and tapered wear. Eliminating chamfers may raise initial bite but can elevate noise in light applications. World-class factories show value through yield improvement, regrind control, tool life extension, and energy efficiency—gains that keep performance steady while reducing total cost. Record microstructure of friction films via SEM for development insights where labs allow. Specify compressibility at operating load to control pedal travel and knockback behavior.

Fleet Duty Cycle Considerations

If you buy Geely brake pads from China for high-mileage fleets, pay special attention to wear rates, rotor compatibility, and hot-resilience. Taxi and ride-hailing cycles demand friction that resists fade and recovers quickly, with compressibility tailored to minimize pedal growth. Consistent density, porosity, and hardness across batches reduce bedding time and improve predictability for drivers who operate in dense traffic with frequent stops. Document permissible ranges for density, hardness, and porosity to maintain consistency. Use mechanical retention features to boost shear strength where packages allow. Validate shim adhesives through hot-soak and peel tests aligned to your internal specs.

As a result, teams that buy Geely brake pads from China can demonstrate repeatable performance and fewer launch issue

Technical Documentation & PPAP

Structured documentation builds trust:

- Drawings with tolerances.

- Control plans and PPAP submissions.

- FMEAs for risk mitigation.

- Certificates of compliance.

When you buy Geely brake pads from China, enforce documentation to prevent costly surprises.

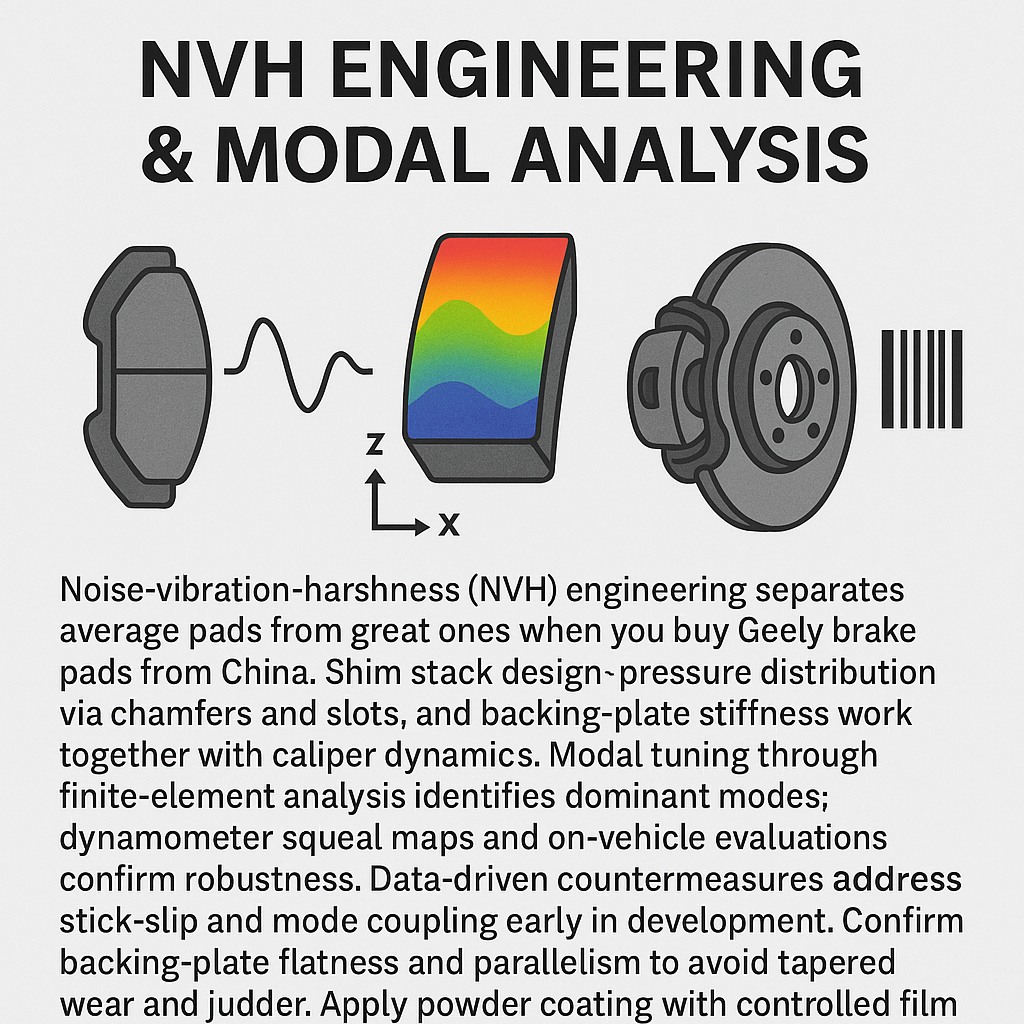

NVH Engineering & Modal Analysis

Noise-vibration-harshness (NVH) engineering separates average pads from great ones when you buy Geely brake pads from China. Shim stack design, pressure distribution via chamfers and slots, and backing-plate stiffness work together with caliper dynamics. Modal tuning through finite-element analysis identifies dominant modes; dynamometer squeal maps and on-vehicle evaluations confirm robustness. Data-driven countermeasures address stick-slip and mode coupling early in development. Confirm backing-plate flatness and parallelism to avoid tapered wear and judder. Apply powder coating with controlled film build to avoid dimensional stack-up issues. Implement barcode or QR traceability linking batch IDs to certificates and reports

Supplier Transparency & Audits

Traceability is vital. Responsible suppliers log batch IDs, heat numbers, and press cycles. Transparent corrective-action reports reinforce confidence. This transparency makes it safer to buy Geely brake pads from China.

Sustainability & ESG Metrics

Factories increasingly highlight sustainability:

- Recycled steel content.

- Heat recovery from ovens.

- Reduced emissions.

Sustainability considerations increasingly influence where you buy Geely brake pads from China. Many plants recover heat from cure ovens, recycle steel scrap from backing-plate stamping, and reduce waste in mixing through digital dosing. Optimized logistics—full-container loads, route planning, and local warehousing—cut emissions while improving lead-time reliability. Publish Environmental Product Declarations where markets demand them. Use design of experiments to screen fiber types, lubricant ratios, and resin content efficiently. Adopt SPC on press pressure, mold temperature, and cure-time windows to shrink variation. Train operators to remove swarf and dust, preventing inclusion defects before bonding.

As a result, teams that buy Geely brake pads from China can demonstrate repeatable performance and fewer launch issues.

Import Regulations & Customs

Every importer must understand Incoterms, HS codes, tariffs, and regional regulations. For example, ECE R90 applies in the EU, copper limits apply in the U.S. Compliance is mandatory when you buy Geely brake pads from China.

Understanding Friction Codes (μ)

For engineers who buy Geely brake pads from China, understanding μ coding prevents mismatches. A pad marked “FF” under SAE J866 indicates a defined coefficient range at both low and high temperature. Moving to “GG” may improve high-energy performance but can change pedal feel. Combine μ codes with compressibility and dyno curves to ensure the whole system meets target stopping distances and noise limits. Cross-check drawing sign-offs, edge codes, and labeling before mass printing. Publish maintenance instructions to reduce early callbacks. Benchmark competitor products to set realistic wear and rotor-compatibility targets.

As a result, teams that buy Geely brake pads from China can demonstrate repeatable performance and fewer launch issues.

Rotor Compatibility & Bedding Procedures

Rotor interactions are central when you buy Geely brake pads from China. High-carbon rotors manage heat and resist crack initiation; drilled or slotted designs help gas evacuation but can concentrate stress. Bedding procedures must deposit uniform friction films—rushed burnish creates hotspots and uneven torque. Teach drivers the post-install routine to stabilize the system and extend service life after pad replacement. Set acceptance criteria for squeal maps under speed, pressure, and temperature sweeps. Deploy automated inspection to detect chips and surface contamination. Lock revision control in PLM so changes propagate cleanly to tooling and packaging

Tendering & RFQ Documentation

Documentation for tenders and RFQs is cleaner when you buy Geely brake pads from China. Provide annual volume forecasts, model fitments with OE numbers, and any weight or material restrictions. Specify packaging (unit, inner, master), labeling content, and pallet patterns. Clarify warranty terms: accepted wear bands, noise thresholds, and return protocols with photos, dyno expectations, and timelines to avoid disputes. Model inventory buffers around vessel cutoffs and holiday periods to maintain fill rate. Align Incoterms, insurance, and port handling to minimize dwell and demurrage. Quantify total cost of ownership including returns and logistics overhead.

Risk Mitigation Strategies

Dual sourcing, safety stock, and vendor scorecards reduce risks. By planning carefully, enterprises can safely buy Geely brake pads from China with minimal disruption.

Role of Steel & Shims

Steel is everywhere in this product, which is why materials knowledge helps you buy Geely brake pads from China. Backing plates rely on the global steel supply chain; understanding steelmaking, recycling rates, and sustainability commitments adds resilience to specifications. Stainless shims and hardware play roles in NVH and corrosion control. Knowing how global steel markets evolve informs long-term contracts and cost models for backing-plate stock. Specify stainless grades compatible with caliper environments and road-salt exposure. Avoid copper contamination where restricted. Use thermal imaging on dyno to monitor hot spots. Confirm guide-pin condition during road tests to prevent false NVH positives.

As a result, teams that buy Geely brake pads from China can demonstrate repeatable performance and fewer launch issues.

Validation from Pilot to SOP

From the first sample to SOP, validation steps protect your reputation when you buy Geely brake pads from China. Golden samples, gauge R&R on measurement systems, and limit samples for visual attributes set expectations. Gradual pilot batches reveal latent issues in mixing, cure, or packaging. Only after stable capability indices should lines be authorized for mass production at committed takt time. Integrate supplier KPIs into quarterly reviews to drive improvement. Establish dual-lane tooling or spare molds to reduce maintenance downtime. Simulate airflow and cooling on vehicles with undertrays to mimic worst-case conditions.

Warranty Performance & Field Feedback

Warranty performance remains the endgame as you buy Geely brake pads from China. Track claims by vehicle model, mileage, and symptom (noise, dust, fade). Feed results into design of experiments to refine chamfers, compressibility, or underlayer density. Factories that close loops between field data and process windows improve faster and hold performance over time across model years. Record microstructure of friction films via SEM for insights where labs allow. Specify compressibility at operating load to control pedal growth. Target stable friction across temperature ranges with minimal torque variation.

As a result, teams that buy Geely brake pads from China can demonstrate repeatable performance and fewer launch issues

Commercial Terms & IP Protection

Commercial terms deserve engineering attention when teams buy Geely brake pads from China. Tie pricing to verified process improvements and stable raw-material indices, with reopeners for force-majeure spikes. Negotiate tooling ownership and maintenance obligations. Ensure confidentiality and IP protection around formulas and caliper-specific NVH countermeasures developed jointly with the supplier. Apply powder coating with controlled film build to balance corrosion resistance and dimension. Implement QR traceability linking batch IDs to certs. Include R90 evidence and J866 edge-code snapshots in PPAP packages..

Digital Tools & Smart Inspection

AI-based vision inspection detects surface flaws early. PLM systems track revisions. These tools enhance reliability when you buy Geely brake pads from China.

Safety & Compliance in Manufacturing

Worker protection is non-negotiable: dust collection, PPE, machine guarding. Buyers who buy Geely brake pads from China should confirm supplier safety audits.

Aftermarket Fitment & Catalog Accuracy

Accurate fitment catalogs reduce returns and boost trust. Buyers who buy Geely brake pads from China must insist on OE cross-references, images, and installation instructions.

Sustainability & Global ESG Reporting

Beyond EPDs, logistics optimization reduces emissions. Reporting builds credibility for enterprises that buy Geely brake pads from China.

G.Sparts Advantage in Sourcing

G.Sparts ensures supplier audits, PPAP validation, and logistics coordination. This makes it safer and easier for global buyers to buy Geely brake pads from China.

Conclusion & Key Takeaways

When you buy Geely brake pads from China, success depends on:

- Verified standards (SAE J866, ISO 6312, ECE R90).

- Documented traceability.

- Controlled production.

- Proven NVH and durability.

- Strong logistics & packaging.

Finally, what should be in your short list when you buy Geely brake pads from China? Verified μ code and dyno curves; compressibility and shear data; backing-plate steel traceability; shim stack design; edge codes and labeling; packaging tests; ECE R90 approval where relevant; and fixed change-control protocols. With these in hand, your team can source confidently and scale reliably with fewer surprises. Benchmark competitors to set realistic wear and rotor-compatibility targets. Establish dual-lane tooling to reduce downtime. Integrate supplier KPIs into quarterly reviews to sustain improvement.

Authoritative External References

- ASTM International — Materials & testing frameworks

- World Steel Association — Industry & sustainability

- Stainless steel – Wikipedia — Metallurgy overview

- NiBK — Disc Rotor Product Family