Top 10 Powerful Reasons to Choose Ceramic Changan Brake Pads China for Superior Performance

Ceramic Changan Brake Pads China – G-Sparts’ Global Advantage

When sourcing reliable auto parts, choosing ceramic Changan brake pads China is essential for ensuring safety, durability, and long-term vehicle performance. G-Sparts has established itself as a trusted supplier of high-quality ceramic brake pads designed specifically for Changan vehicles. With advanced production facilities and strict adherence to international standards, the company delivers products that exceed customer expectations. Ceramic brake pads are known for their quiet operation, superior heat resistance, and reduced wear on brake rotors compared to traditional alternatives. G-Sparts combines technical expertise with strong supply chain capabilities, making it the go-to supplier for both domestic and international markets. Businesses and vehicle owners alike benefit from reliable, cost-effective brake pad solutions backed by proven engineering excellence.

What Are Ceramic Brake Pads?

Ceramic brake pads are a modern solution in automotive braking systems, developed to provide improved performance and longevity compared to earlier friction materials. Unlike semi-metallic or organic pads, ceramic Changan brake pads China are manufactured using a composite of ceramic fibers, nonferrous materials, and bonding agents. This unique structure results in minimal dust generation, quieter braking, and excellent stability at high temperatures. They also produce less vibration, contributing to a smoother driving experience. G-Sparts ensures that its ceramic pads are engineered for precise fit and optimal performance on Changan vehicles. These pads combine safety, comfort, and durability, making them a preferred choice for drivers seeking superior braking performance in both city and highway conditions.

Why Changan Vehicles Need Ceramic Brake Pads

Changan vehicles, known for their versatility and growing global popularity, require brake components that meet demanding performance standards. Ceramic Changan brake pads China provide the perfect balance of safety, comfort, and efficiency tailored to these vehicles. The ceramic formulation offers reduced rotor wear, ensuring longer service life and fewer replacements. Drivers experience quieter stops, even under heavy braking, which is particularly valuable in urban environments where frequent stops are common. Additionally, the thermal stability of ceramic pads enhances performance during high-speed driving or when carrying heavy loads. G-Sparts designs and supplies brake pads optimized for Changan sedans, SUVs, and commercial vehicles, ensuring customers benefit from dependable braking performance in every driving condition.

Key Advantages of Ceramic Changan Brake Pads China

The adoption of ceramic Changan brake pads China offers multiple benefits over other brake pad types. One of the most significant advantages is their ability to minimize noise, vibration, and harshness (NVH), resulting in a more comfortable driving experience. Ceramic brake pads also generate finer, lighter-colored dust compared to semi-metallic pads, keeping wheels cleaner. Their superior heat resistance prevents brake fade, ensuring consistent stopping power in demanding conditions. Furthermore, they extend the life of brake rotors by reducing abrasive wear, lowering long-term maintenance costs. G-Sparts enhances these advantages with precision manufacturing, ensuring that each brake pad provides reliable fitment, durability, and safety for all Changan vehicles across diverse applications worldwide.

Industry Standards and ASTM Compliance

When selecting ceramic Changan brake pads China, compliance with global quality standards is essential. G-Sparts ensures all brake pads meet stringent ASTM International requirements, covering material composition, performance testing, and safety. Additionally, the company adheres to ISO standards for automotive components, guaranteeing global acceptance and reliability. Each product undergoes friction testing, heat resistance analysis, and wear evaluation to confirm compliance. Customers benefit from full traceability and certification, ensuring that brake pads are not only durable but also safe under all driving conditions. By maintaining strict compliance with recognized international standards, G-Sparts strengthens its position as a dependable supplier of ceramic brake pads for Changan vehicles across worldwide markets.

G-Sparts as a Trusted Supplier in China

As a leading provider of ceramic Changan brake pads China, G-Sparts stands out for its commitment to quality, innovation, and customer satisfaction. The company operates state-of-the-art manufacturing facilities equipped with advanced production lines and quality testing laboratories. With years of experience in automotive spare parts, G-Sparts has developed expertise in producing brake pads that match or exceed OEM specifications. Its reputation extends globally, supported by efficient export operations and a strong network of distribution partners. Beyond manufacturing, G-Sparts provides technical consultation and customer service, ensuring clients receive tailored solutions for their specific needs. This holistic approach makes G-Sparts the preferred choice for businesses sourcing premium ceramic brake pads.

Manufacturing Process of Ceramic Brake Pads

The production of ceramic Changan brake pads China requires precision engineering and advanced materials science. The process begins with carefully measured raw materials such as ceramic fibers, fillers, bonding resins, and small amounts of nonferrous metal powders. These ingredients are mixed to form a consistent friction material, which is then pressed into molds under high pressure. After pressing, the pads undergo a sintering process in high-temperature furnaces, ensuring structural integrity and heat stability. Once cured, the pads are bonded to backing plates and undergo surface grinding for precise thickness. G-Sparts applies strict quality control at every stage, ensuring each brake pad delivers superior performance, durability, and safety for Changan vehicles in real-world conditions.

Testing and Quality Assurance

As a leading supplier of ceramic Changan brake pads China, G-Sparts emphasizes rigorous testing to guarantee reliability. Each brake pad undergoes comprehensive evaluations, including coefficient of friction testing, wear resistance analysis, and thermal cycling assessments. Noise, vibration, and harshness (NVH) tests are performed to ensure quiet operation across various driving conditions. Advanced dynamometer testing simulates high-speed braking and heavy load scenarios, replicating real-world stresses. Every batch is checked for compliance with ASTM International and ISO standards, with results documented for full traceability. By implementing these stringent quality assurance measures, G-Sparts ensures customers receive brake pads that consistently meet safety regulations, enhance driving comfort, and reduce long-term maintenance costs.

Applications Across Changan Vehicle Models

The versatility of ceramic Changan brake pads China makes them suitable for a wide range of Changan vehicles. For passenger sedans, ceramic pads provide quiet operation and smooth braking, ideal for daily commuting in urban settings. SUVs benefit from their superior heat resistance and durability, ensuring consistent performance under heavier loads and long-distance travel. In commercial vehicles such as vans and light trucks, the extended lifespan and reduced rotor wear lower operational costs. G-Sparts engineers brake pads tailored to each model’s specific braking system, guaranteeing proper fitment and optimized stopping power. This model-specific approach ensures that Changan drivers experience enhanced safety and reliability regardless of vehicle type or driving environment.

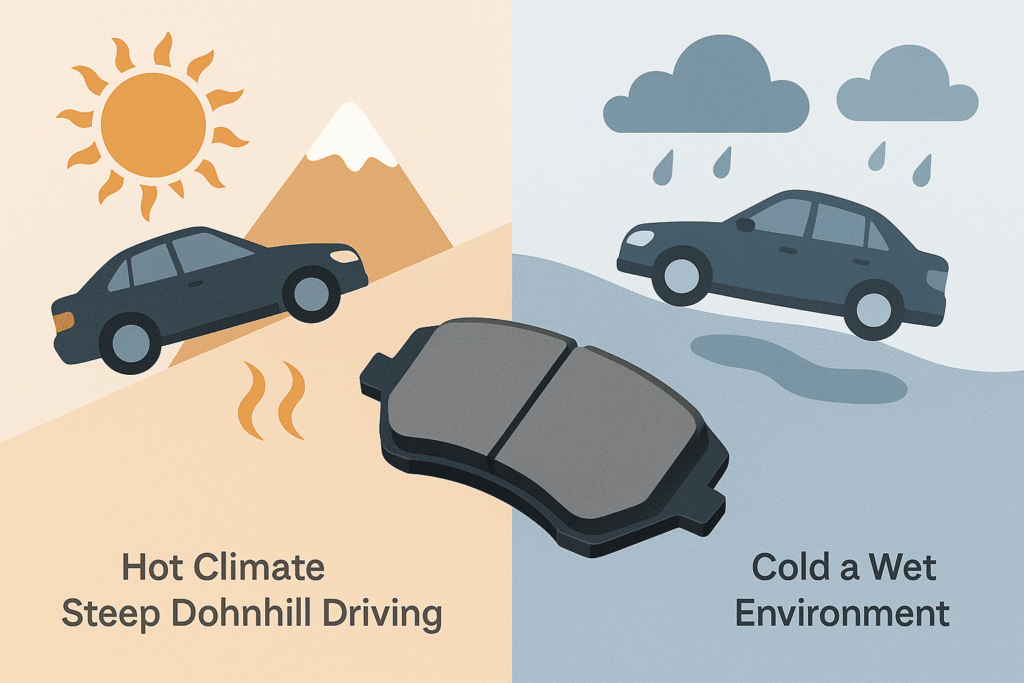

Performance in Extreme Conditions

Durability in extreme conditions is a hallmark of ceramic Changan brake pads China. G-Sparts designs its pads to withstand high thermal loads generated during continuous braking, ensuring resistance against brake fade. In hot climates or during steep downhill driving, ceramic pads maintain stable friction levels, providing consistent braking power. In cold or wet environments, they perform reliably, minimizing the risk of compromised safety. Their resistance to rotor wear further enhances longevity, even under heavy-duty applications. By simulating demanding road conditions during testing, G-Sparts guarantees that its brake pads meet the expectations of both urban drivers and those tackling long-distance or high-performance driving scenarios with Changan vehicles.

Sustainability and Eco-Friendly Production

Modern consumers value sustainable solutions, and ceramic Changan brake pads China align well with eco-friendly goals. Unlike older formulations containing asbestos or heavy metals, ceramic brake pads are manufactured with environmentally safe materials. G-Sparts prioritizes green production practices, including the recycling of manufacturing scrap and the use of energy-efficient furnaces. Ceramic pads produce less brake dust compared to semi-metallic pads, reducing environmental pollution and keeping wheels cleaner. Their long service life also reduces waste from frequent replacements. By committing to sustainability in both product design and production, G-Sparts supports the automotive industry’s move toward greener technologies while providing customers with safe, reliable, and eco-conscious brake solutions.

Strengthening Global Competitiveness

In today’s highly competitive automotive market, sourcing reliable components like ceramic Changan brake pads China is essential for staying ahead. G-Sparts leverages its manufacturing expertise, adherence to ASTM and ISO standards, and robust export capabilities to compete successfully on a global scale. By maintaining cost efficiency without sacrificing quality, the company helps international distributors and fleet operators maximize profitability. Its strategic focus on innovation, customer service, and sustainability ensures long-term relevance in rapidly evolving markets. Whether for OEM contracts or aftermarket distribution, G-Sparts delivers products that meet diverse client needs worldwide. This combination of technical excellence and business reliability positions G-Sparts as a true global leader in the ceramic brake pad industry.

Global Supply Chain Capabilities

As a trusted exporter of ceramic Changan brake pads China, G-Sparts has built a robust global supply chain. The company partners with logistics providers to ensure reliable, on-time delivery across Asia, Europe, the Middle East, Africa, and the Americas. Its strong distribution network allows customers to access consistent inventory levels, even during peak demand. By combining advanced inventory management systems with efficient warehousing, G-Sparts minimizes lead times and optimizes customer satisfaction. Flexible shipping options support both small orders and bulk consignments, accommodating the needs of businesses worldwide. This global reach, supported by professional logistics coordination, strengthens G-Sparts’ reputation as a dependable supplier in the competitive automotive spare parts market.

Cost-Effectiveness of Ceramic Pads

While initial costs may be slightly higher, ceramic Changan brake pads China offer long-term value that outweighs alternatives. Their resistance to wear significantly reduces replacement frequency, lowering maintenance expenses for vehicle owners. Additionally, ceramic pads cause less damage to rotors, extending the lifespan of the braking system. Their quiet operation and consistent performance reduce driver stress and improve overall satisfaction. For fleet operators and commercial vehicle owners, the reduced downtime and lower operational costs provide measurable savings. G-Sparts emphasizes affordability without compromising quality, ensuring clients achieve the perfect balance between cost-efficiency and performance. This makes ceramic brake pads an excellent investment for Changan vehicles across global markets.

Customer Testimonials and Case Studies

The reliability of ceramic Changan brake pads China is validated through customer experiences worldwide. Fleet managers report significant reductions in maintenance costs after switching to G-Sparts’ ceramic pads, citing fewer replacements and improved performance under heavy use. Individual Changan owners highlight quieter braking and cleaner wheels, enhancing driving comfort. Case studies also show that commercial clients operating delivery vans and light trucks have achieved longer service intervals, reducing downtime and increasing profitability. G-Sparts leverages this feedback to continuously refine its products and meet evolving customer needs. These real-world examples reinforce the company’s reputation as a trusted partner for reliable and cost-effective braking solutions.

Comparing Ceramic vs Semi-Metallic Brake Pads

When choosing between brake pad types, many customers compare ceramic Changan brake pads China with semi-metallic options. Semi-metallic pads offer strong stopping power but tend to generate more noise, vibration, and brake dust, which can damage rotors and increase maintenance. Ceramic pads, in contrast, deliver quieter operation, cleaner wheels, and longer service life. While semi-metallic pads may perform well in heavy-duty applications, ceramic pads provide consistent braking across everyday driving conditions and high temperatures without excessive wear. G-Sparts advises clients based on specific vehicle usage, but for Changan drivers seeking comfort, safety, and cost efficiency, ceramic brake pads remain the superior choice across most applications.

Future of Ceramic Brake Pads in the Automotive Industry

The future of ceramic Changan brake pads China looks promising as global demand for advanced braking solutions continues to grow. With the rise of electric and hybrid vehicles, brake pads are required to meet higher standards for quiet operation, minimal dust, and consistent performance. Ceramic technology aligns perfectly with these needs, ensuring long-term relevance in the evolving automotive market. G-Sparts is actively investing in research and development to enhance thermal resistance, friction stability, and eco-friendly production techniques. By anticipating industry trends and customer demands, the company positions itself as a forward-thinking supplier, ensuring its ceramic brake pads remain at the forefront of innovation and global competitiveness.

Customized Brake Pad Solutions

Every market has unique demands, and G-Sparts meets them by offering tailored ceramic Changan brake pads China solutions. Customers can choose from different friction formulations, thickness variations, and pad shapes to suit specific Changan models and driving conditions. Whether a client needs OEM-standard replacements for passenger cars or performance-oriented pads for commercial vehicles, G-Sparts delivers precision-engineered products. The company also supports custom branding and packaging for distributors, enabling stronger market positioning. By focusing on customization, G-Sparts ensures its partners gain a competitive edge while vehicle owners receive ceramic Changan brake pads China that perform exactly as required, from daily commuting to heavy-duty operations in challenging road environments.

Building Long-Term Client Partnerships

Beyond supplying high-quality ceramic Changan brake pads China, G-Sparts emphasizes building strong, long-lasting relationships with its customers. The company provides dedicated account managers, technical consultation, and after-sales support, ensuring clients receive reliable service at every step. This relationship-driven approach helps distributors, fleet operators, and retailers plan procurement confidently, knowing they can depend on consistent quality and timely delivery. Over time, G-Sparts has developed a loyal customer base across multiple continents by prioritizing transparency, reliability, and innovation. By focusing on partnership rather than one-time transactions, the company fosters trust and collaboration, which ultimately strengthens its global presence in the competitive automotive spare parts market.

Innovation Driving Future Growth

A forward-looking approach keeps G-Sparts ahead in the competitive world of ceramic Changan brake pads China. The company invests in research and development to explore new friction materials that provide even greater durability, quieter performance, and enhanced heat resistance. By leveraging advanced testing technologies and working with international automotive experts, G-Sparts continues to refine its product portfolio. These innovations not only benefit Changan vehicle owners but also align with future mobility trends such as electric and hybrid vehicles, where efficiency and silence are paramount. Through continuous innovation, G-Sparts ensures that its ceramic Changan brake pads China remain a benchmark in quality, setting new standards for the global automotive spare parts industry.

FAQs on Ceramic Changan Brake Pads China

1. What makes G-Sparts a trusted supplier of ceramic Changan brake pads China?

G-Sparts offers ASTM- and ISO-compliant brake pads designed for safety, durability, and global distribution reliability.

2. How do ceramic brake pads differ from other types?

Ceramic pads provide quieter braking, less dust, and reduced rotor wear compared to semi-metallic or organic brake pads.

3. Are ceramic brake pads suitable for all Changan vehicles?

Yes. G-Sparts manufactures pads tailored for Changan sedans, SUVs, and commercial vehicles, ensuring proper fit and performance.

4. Do ceramic brake pads work well in extreme conditions?

Absolutely. Ceramic pads are tested to perform reliably in high temperatures, wet conditions, and heavy-load driving scenarios.

5. Are ceramic Changan brake pads China eco-friendly?

Yes. They are made without asbestos or heavy metals and generate less brake dust, reducing environmental impact.

6. Can G-Sparts supply bulk orders internationally?

Yes. G-Sparts has strong export logistics, ensuring timely global delivery of ceramic Changan brake pads China.

Conclusion

Selecting ceramic Changan brake pads China is an investment in safety, reliability, and cost efficiency. G-Sparts has established itself as a global leader by delivering high-quality ceramic pads that meet international standards while offering superior braking performance for Changan vehicles. From advanced manufacturing processes to rigorous testing and sustainability initiatives, the company ensures every product is built for long-term success. Its global logistics network and customer-focused approach further strengthen its reputation as a trusted partner. For vehicle owners, distributors, and fleet operators, G-Sparts provides not only premium ceramic brake pads but also peace of mind through dependable supply and technical excellence.

Authoritative External References

- ASTM International — Materials & testing frameworks

- World Steel Association — Industry & sustainability

- Stainless steel – Wikipedia — Metallurgy overview

- NiBK — Disc Rotor Product Family